OUR FACILITIES

-

-

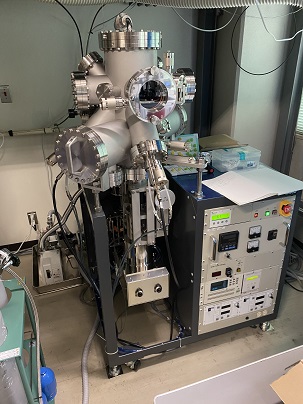

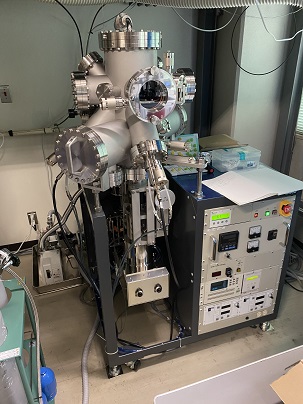

Multi-target sputtering machine (DC×2+RF×1(selective), max 500 deg.)

-

-

Vertical Bridgman furnace

-

-

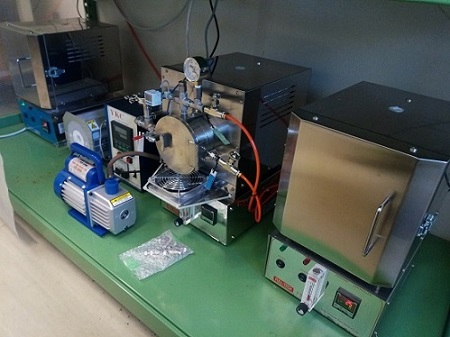

Pt coater

-

-

Economical CVD equipment

-

-

Resistive thermal evaporation (3 sources)

-

-

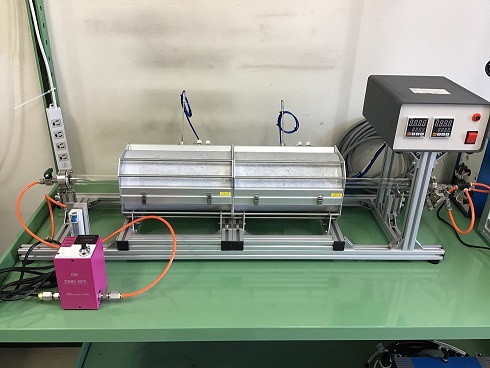

Floating zone furnace

(transferred from Dept. of Physics, U Tokyo

(laboratories of Prof. Hasegawa and Prof. Uchida))

-

-

RF-sputtering machine (3 cathodes; one for magnetic materials)

(transferred from Dept. of Mechano-Informatics, U Tokyo

(laboratory of Prof. Shimoyama))

-

-

3-zone furnace

-

-

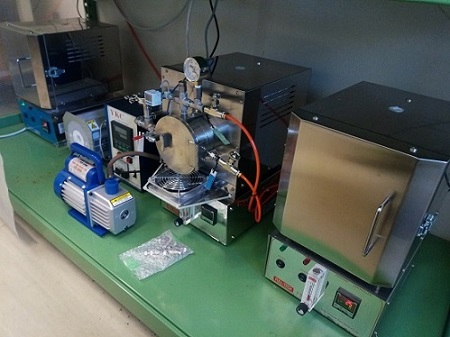

Electric furnaces (box furnaces, tube furnace, vacuum furnace)

-

-

manual 2D transfer system

-

-

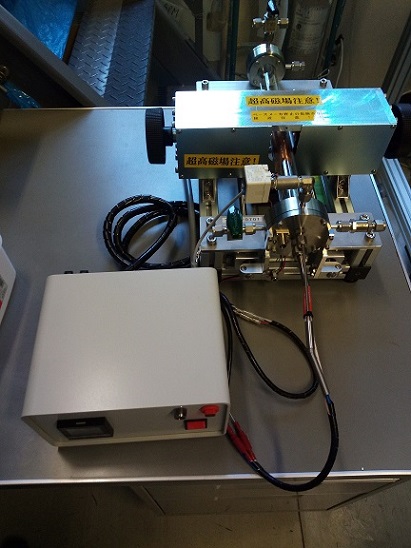

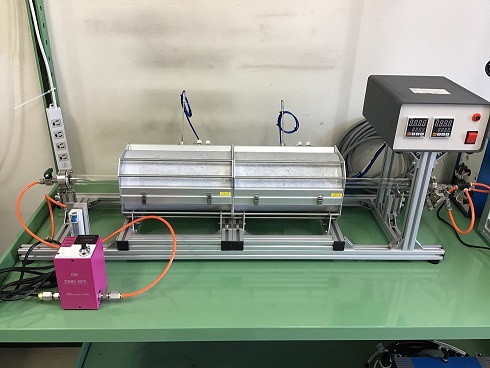

Magnetic annealing furnace (max 220 deg.)

-

-

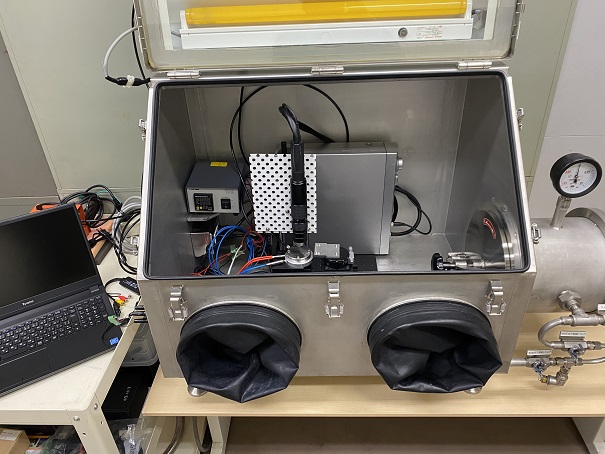

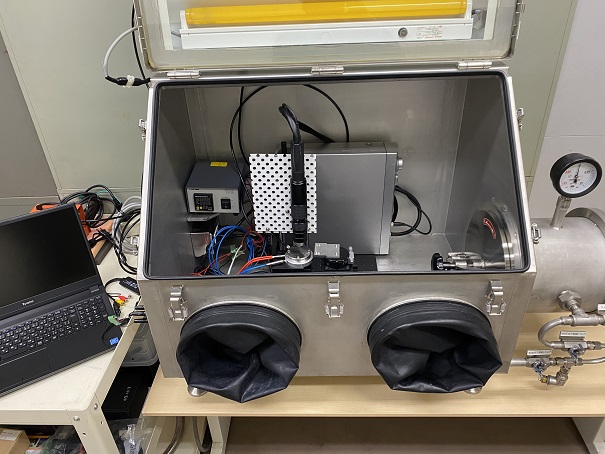

Glovebox

-

-

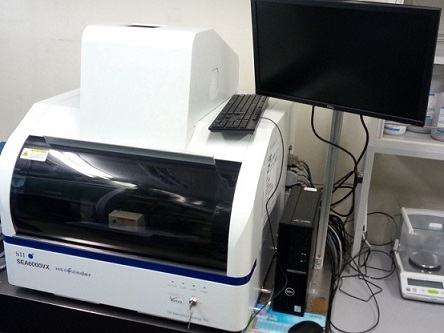

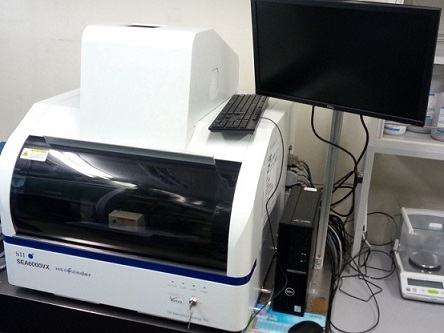

X-ray fluorescence spectrometer (XRF)

-

-

electrolytic crystallization system (in incubator)

-

-

Draft chamber (UV Ozone Cleaner, Ultrasonic Cleaner, Hot Plate), Drying Oven

-

-

Low Speed Saw

-

-

Polisher

-

-

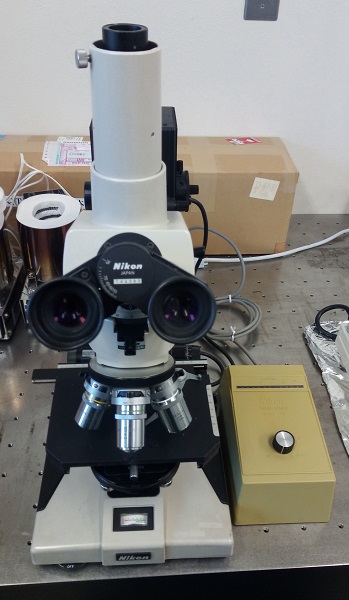

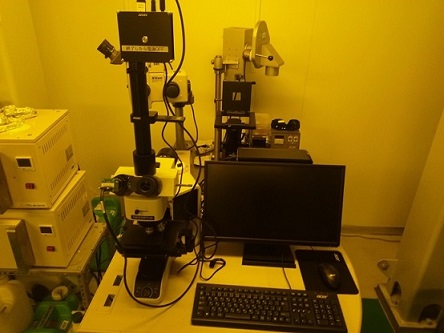

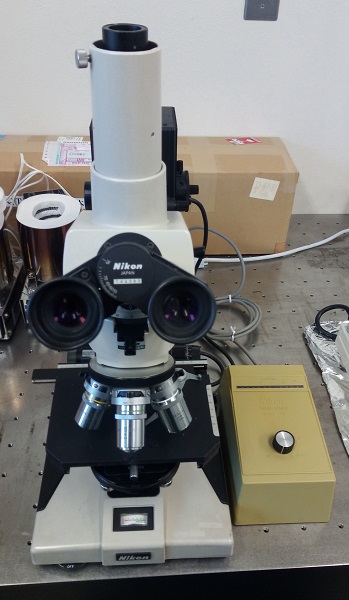

Metallographic Microscope (+differential interferometer)

-

-

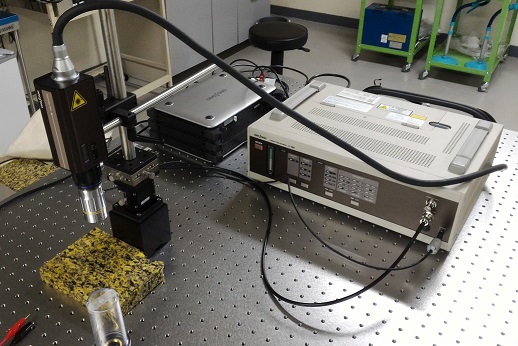

Laser Microscope

-

-

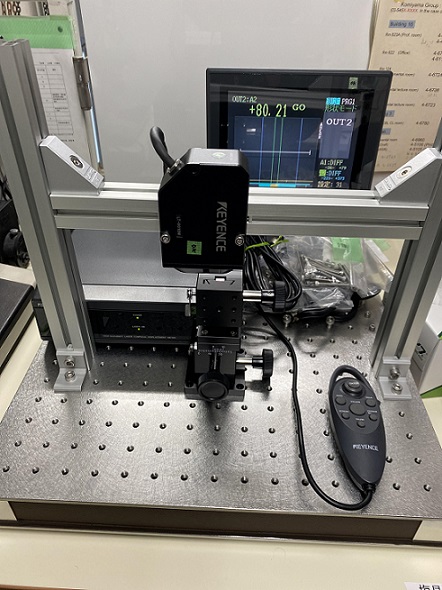

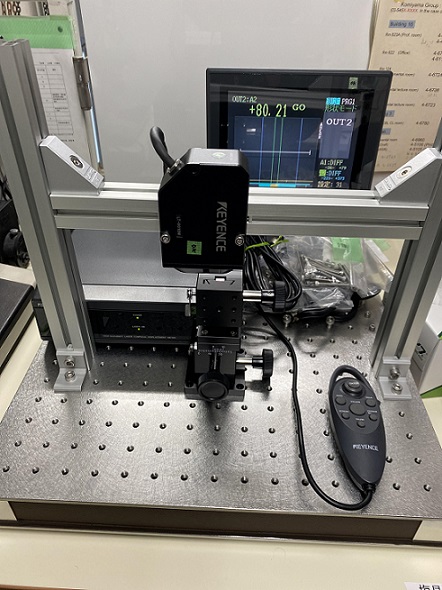

Laser Displacement Meter

-

-

Real Surface View (SEM) VE-7800

-

-

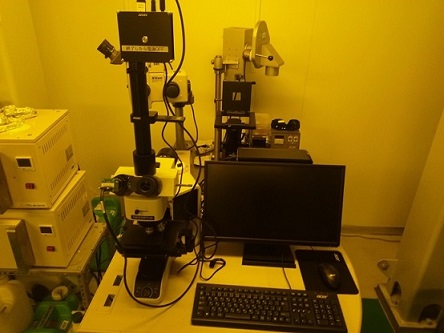

Maskless Lithography

-

-

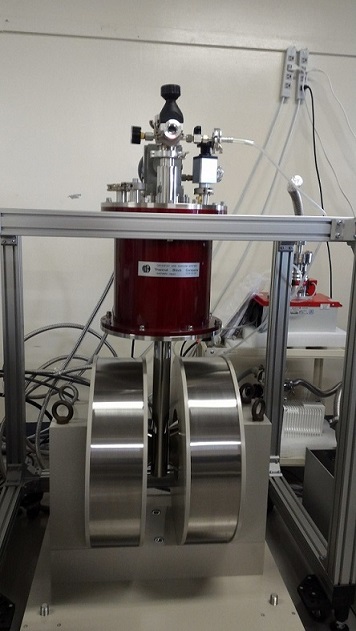

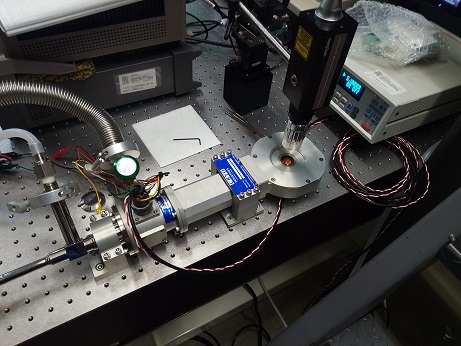

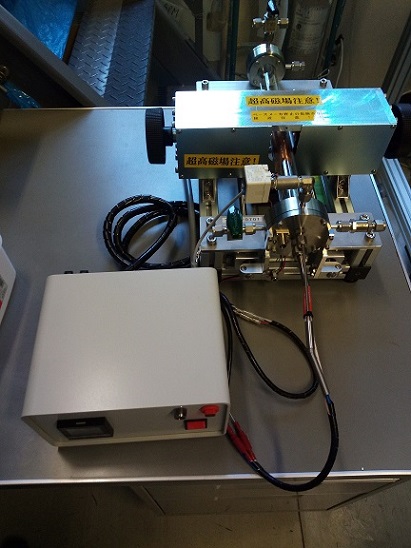

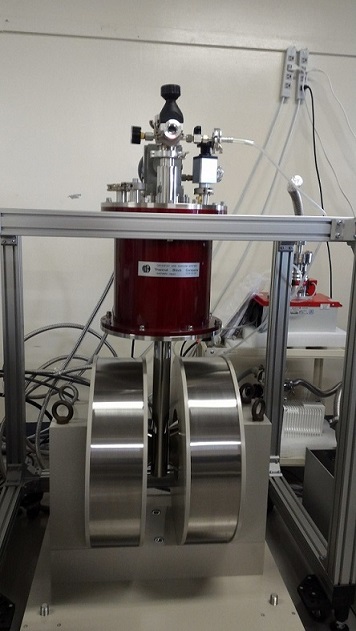

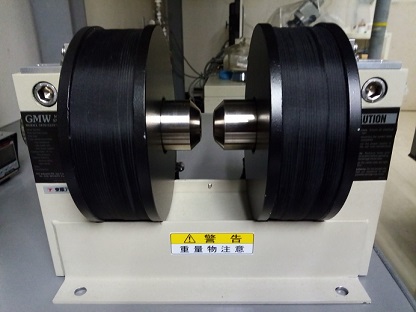

GM Cryocooler + Electromagnet(max. 1T)+ Motorized rotation stage

-

-

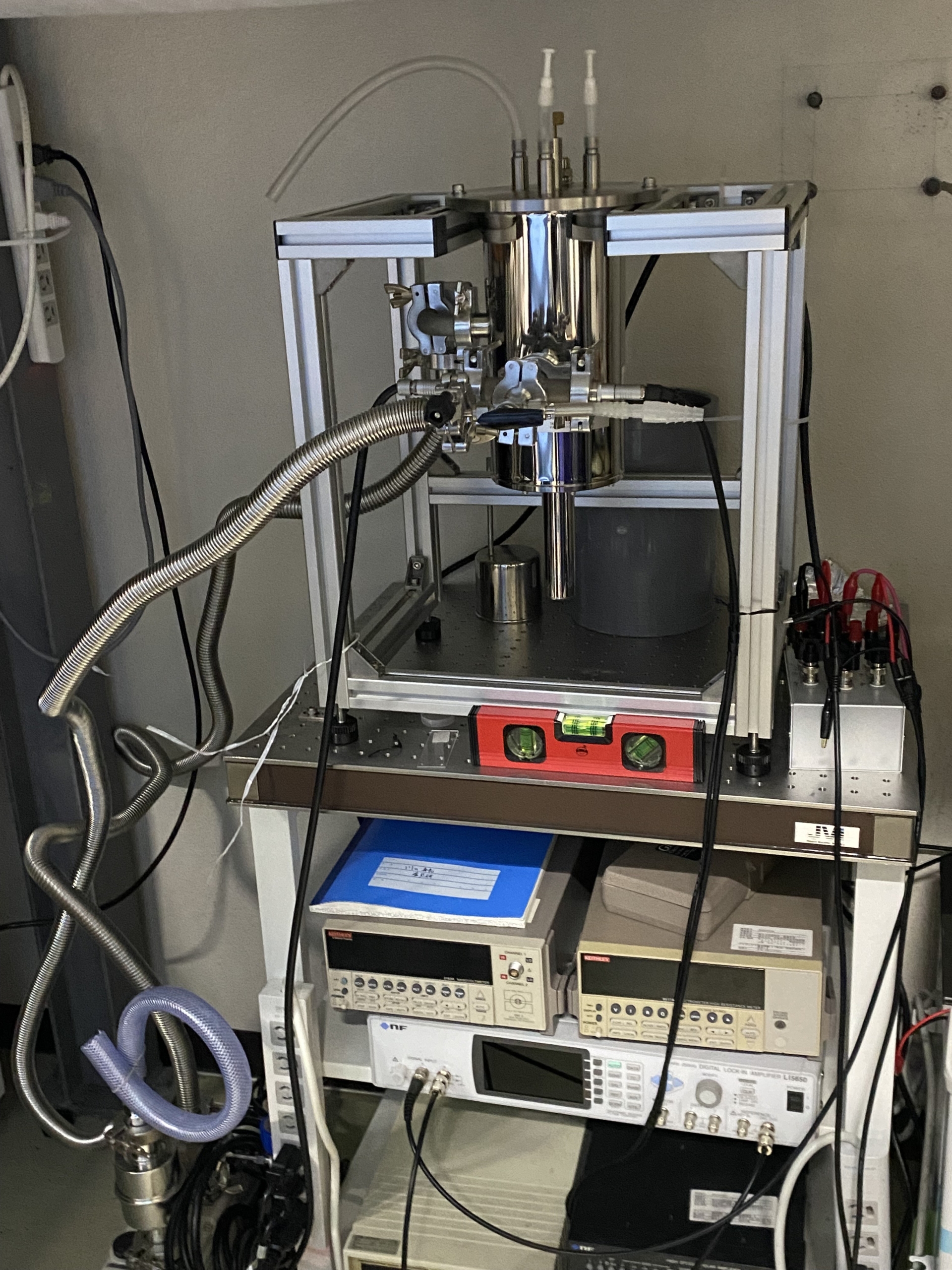

N2 cryostat

-

-

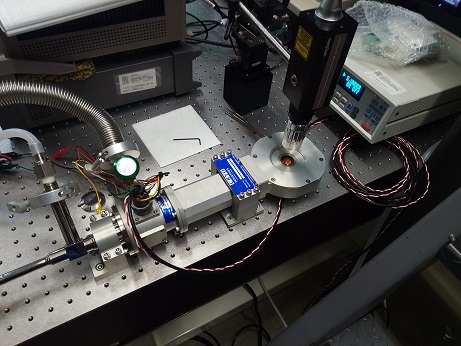

Laser Doppler Vibrometer + FFT Analyzer

-

-

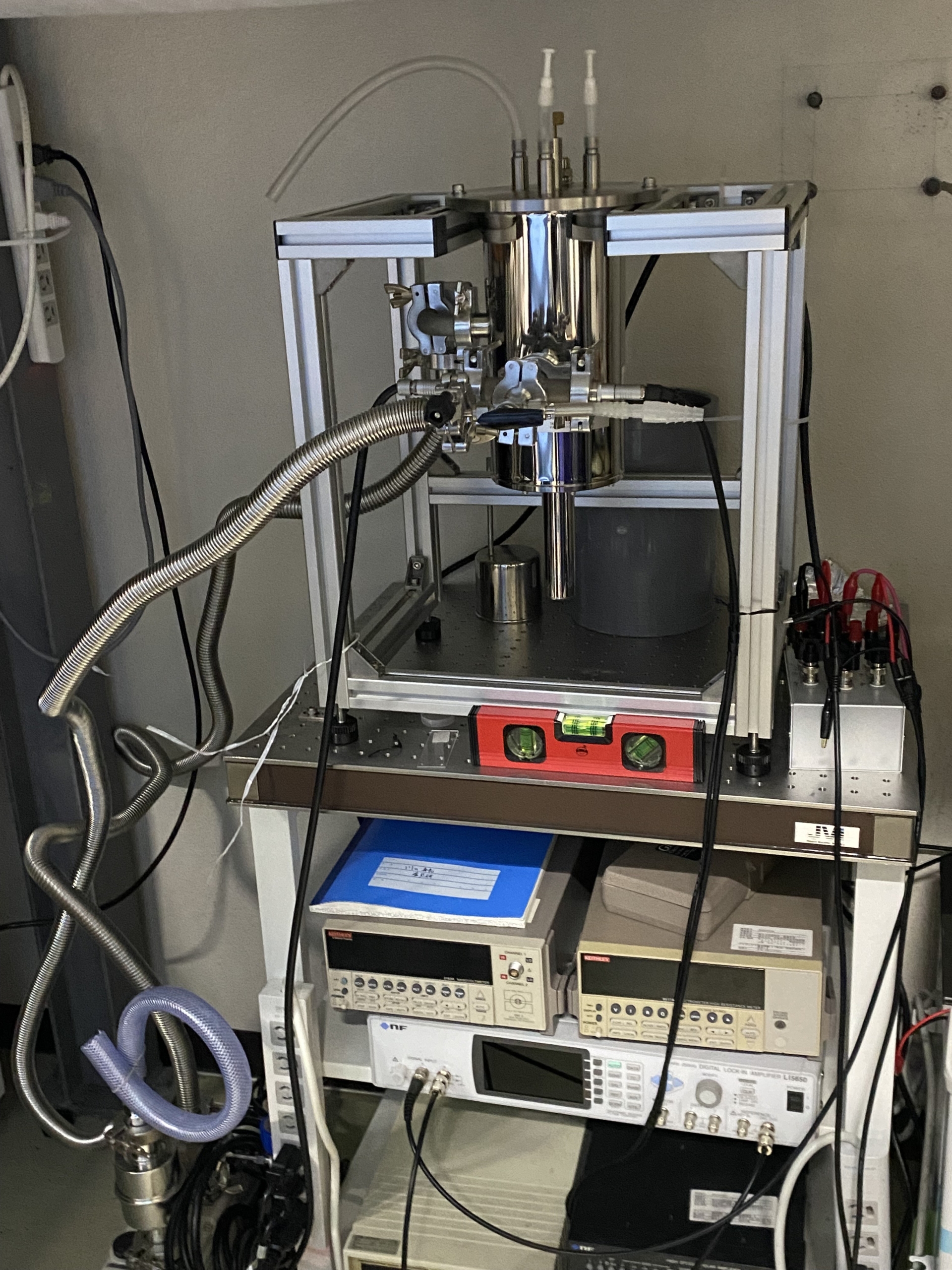

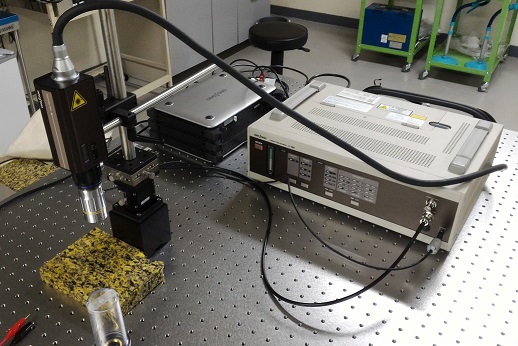

He Optistat (with Laser Doppler Vibrometer)

-

-

laser-based MOKE system

-

-

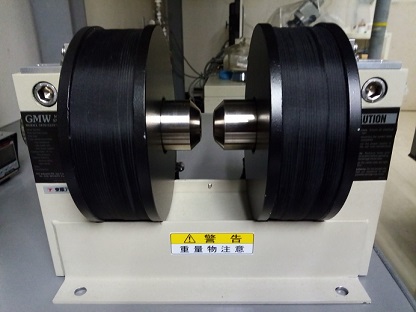

1.2T electromagnet

-

-

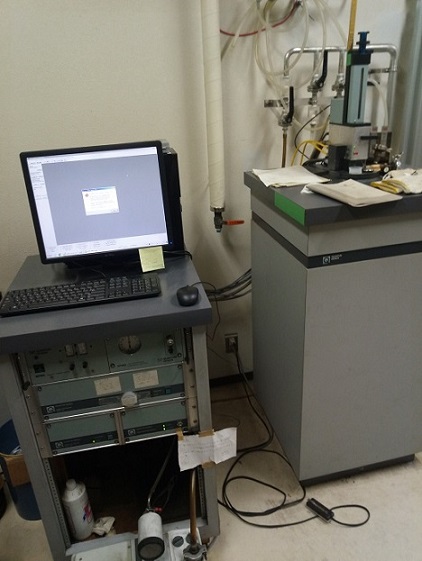

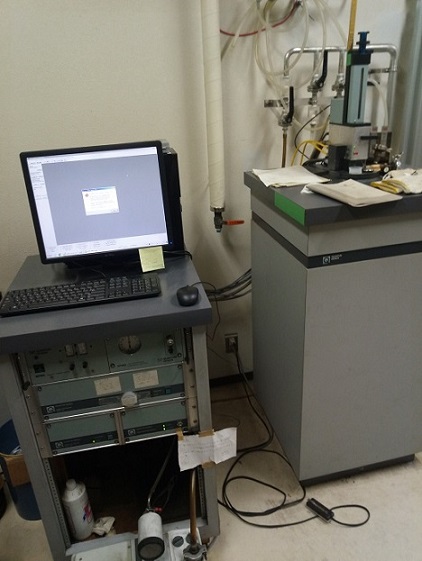

PPMS-9T

(transferred from NEC corporation)

-

-

PPMS-9T(transferred from A. Maeda lab.)

-

-

MPMS-5T

(Common Equipment in Dept. of Basic Science)

Scroll to top